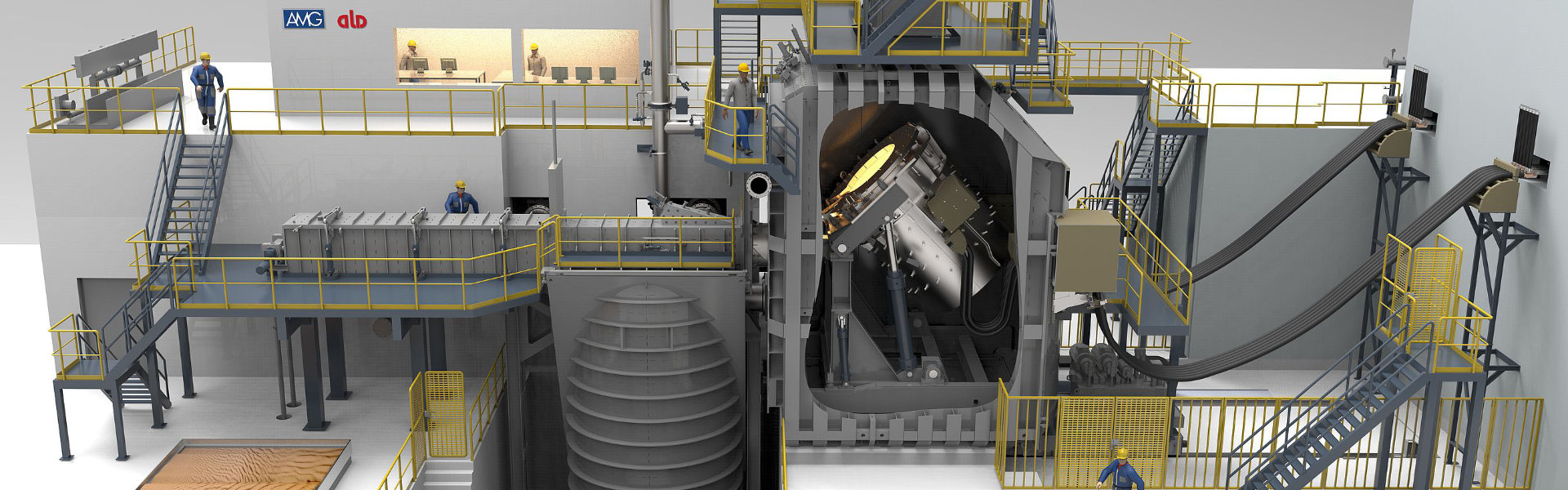

ALD

ALD Vacuum Technologies GmbH is one of the world's leading manufacturer of vacuum equipment for vacuum metallurgy and heat treatment. They set standards through innovative products, state-of-the-art technology, comprehensive service and maximum flexibility.

Industry: Mechanical and plant engineering

Locations: locations in 10 countries

Annual turnover: €160M

Employees: 900 employees

"clevercure helps us avoid system disruptions and hence reduce non-value-added activities to a minimum."

Albrecht Höfler, Vice President Procurement ALD Vacuum Technologies GmbH

Our Path to End-to-End Supply Chain

ALD Vacuum Technologies GmbH based in Hanau close to Frankfurt targeted an end-to-end digital supply chain. Read the interview with Albrecht Höfler, Vice President Procurement at ALD, to find out what other companies can learn form his strategic considerations.

Mr. Höfler, what has been your main reason for starting a project about an end-to-end digital supply chain? What was and is your vision in this respect?

We want our vision of a "digital supply chain" to become true. Not only as an end in itself but to increase efficiency in procurement. It's about avoiding system disruptions, which are the number one source of errors in procurement just as in every other organizational unit, and reducing administrative and hence non-value-added activities to a minimum. We also want to increase the transparency of processes and costs.

What were your steps toward the digital supply chain?

As a first step, we wanted to use SAP functionalities for demand determination and order specification more extensively as starting point for a seamless interaction and integration with our curecomp SRM system. This way, not only the biggest and most important suppliers but a variety of suppliers can be connected to the benefit of all procurement processes. It was important that the system could be used easily and intuitively, especially for smaller suppliers. By means of the "BANF Cockpit" (roughly: "Requisition Cockpit") by clevercure, we were able to implement a continuous "Requisition-to-Pay" process.

What new opportunities for internal and external processes have opened up with the use of the clevercure solution?

Along with increased efficiency and reduced workload thanks to the operational integration of the suppliers, we're relying on structured and standardized workflows, which we can design ourselves based on our requirements without any help from external consultants. As a result, the internal processes become more transparent and we're automatically reminded by the system when an action is required or due. Our employees can now focus on procurement itself instead of the administrative tasks related to it. These workflows also help us to overcome the borders between the internal and external participants in the corresponding processes. To "spare" the suppliers, they are only actively involved in the respective processes based on events. Hence, these external participants don't have any extra work with registering and monitoring to-dos in a portal, which they quite appreciate.

How is the digital supply chain controlled and monitored at ALD?

For management and control purposes, we're mainly using dashboards, which the users can design themselves, and active reporting by clevercure to the buyers responsible. Users can hence immediately view the information relevant to them. By means of the data integration across system borders, data from external systems have been integrated into the dashboards as it's not the task of the buyers to gather up the data but to interpret them.

What were your main reasons for choosing clevercure by curecomp?

We wanted a flexible solution that allows the users to design processes, workflow structures and data structures themselves and to change them, if required, without any help from external consultants. This simultaneously gives us great flexibility regarding process changes and control over our costs. As a medium-sized enterprise, it was important to us to find a partner who understands our needs and who works with us to reach the defined goals. In this respect, we had a very positive experience with the competent team of curecomp.

What is your résumé regarding the expectations and results?

It's been a few months now that we've placed the first modules in operation. The roll-out to the suppliers is also in progress, and workflows have made our internal work better organized and more transparent. So we've achieved what we set out to do. We want to strongly push the roll-out to the suppliers to be able to harness the resulting increase in efficiency as soon as possible.

What are your next steps toward the digital supply chain?

The next modules by clevercure to be implemented are the catalog module for operational tasks and the supplier evaluation module for strategic tasks. In our opinion, the supply chain is not a one-time project but a modern approach based on the motto "Standing still means falling behind".

What are your recommendations for other companies that want to implement a similar project like ALD?

To ensure the acceptance and the success of such a project, it's essential to prepare the content and involve all colleagues affected. The solution partner should and must offer a standard solution that simultaneously offers flexibility for individual process changes but without the need to pay for every single change to a field or additional data structures. We've found the perfect partner for our digital supply chain with clevercure by curecomp.

11/2017

Projektstart

03/2018

Go Live (Bestellprozess)

05/2019

Start Workflows

05/2019

Start Anfrageprozess

Do you have any questions? We'll show you the right path.

Get in touch with us now to find out how similar companies have significantly improved their purchasing processes.